Miner

The new standard in

Material Flow AnalysisThroughput optimization with process mining

Book demoDiscover

Stay ahead of complex material flows

Reveal the hidden waste in your production lines with advanced process mining. The Miner software analyzes event logs from your production history to automatically identify bottlenecks, process variations, and excess inventory.

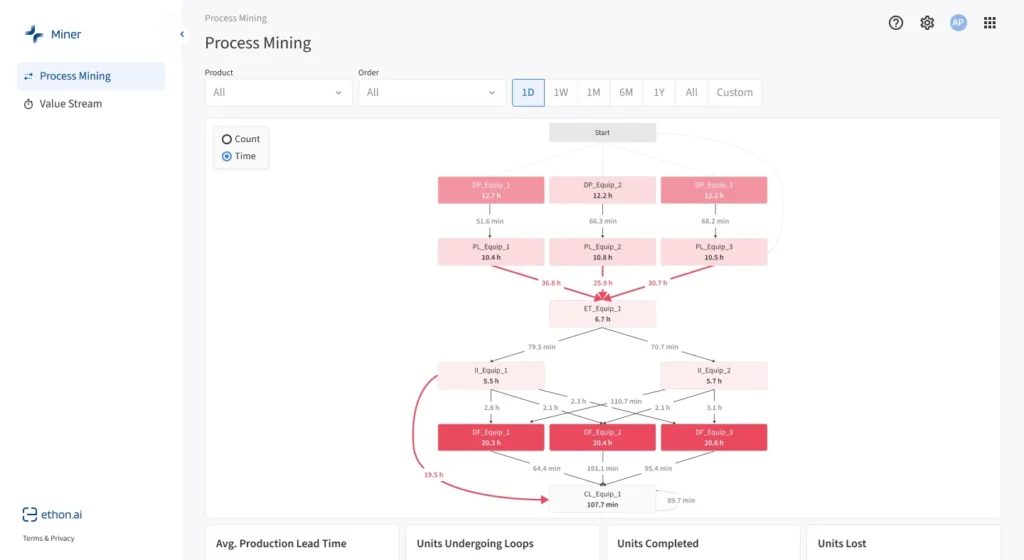

Process Mining

Dive deep into your operational history to uncover hidden inefficiencies and bottlenecks.

Dynamic Analysis

Analyze your material flow for any given point in time. Avoid missing issues due to averaging or snapshotting.

Seamless Integration

Integrate effortlessly with ERP, MES, and real-time part tracking systems.

Capabilities

Material flow analysis has never been easier

Dynamic flow analysis

Through dynamic analysis of process flows, the Miner software provides a comprehensive view of work-in-progress and production throughput. It offers an evolving view of your production processes by tracing each part’s journey through your factory.

At a glance

- Visualize material flows over time.

- Pinpoint exact locations and causes of production delays.

- Proactively detect and address emerging bottlenecks.

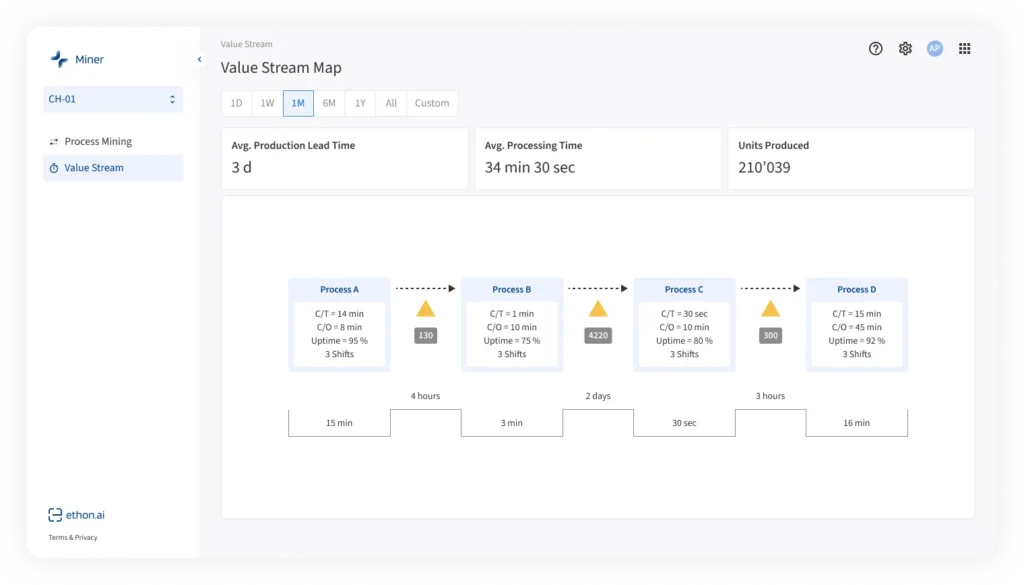

Automated value stream analysis

The Miner software brings a new level of capability to value stream analysis. With this tool, you can easily generate comprehensive material flow maps for any time range in your production history.

At a glance

- Identify excessive buffer inventories that lead to waste.

- Accurately measure cycle times for different process stages.

- Replace time-consuming and error-prone manual assessments on the factory floor.

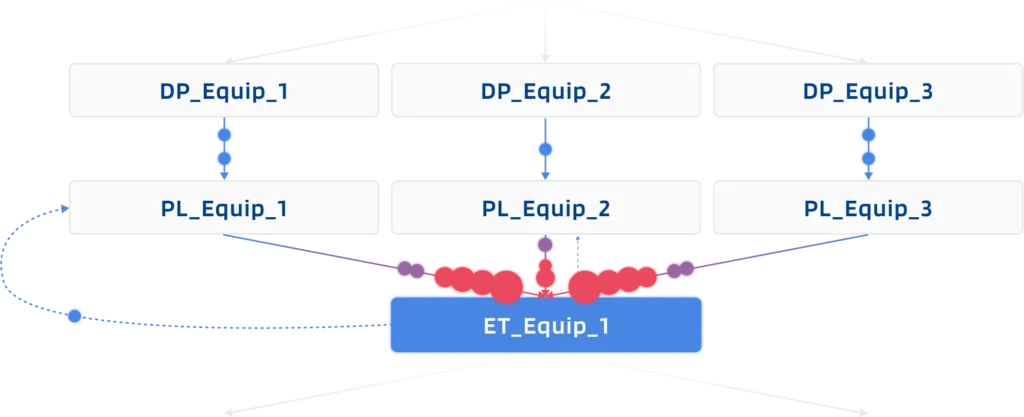

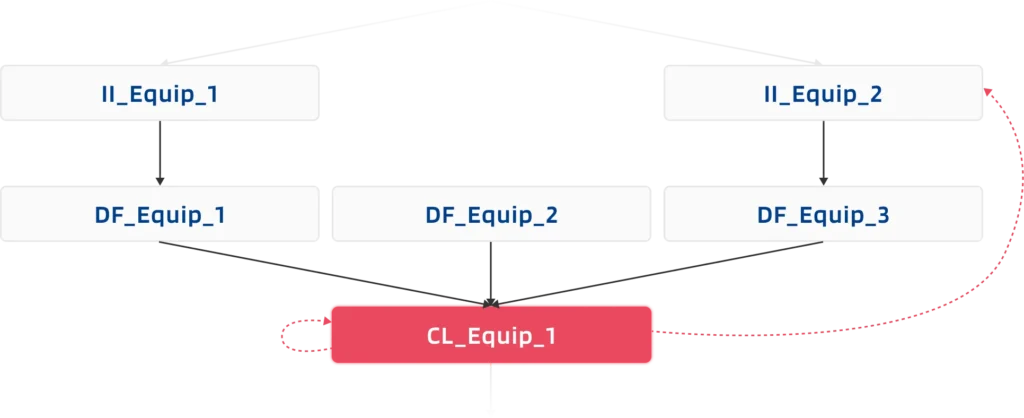

Real-time variance analysis

Ensure your processes adhere to predefined standards with the Miner’s capabilities for conformance analysis. Instantly identify when and where deviations occur in real-time.

At a glance

- Monitor process conformance in real-time.

- Pinpoint unintended loops and rework.

- Flag deviations from the predefined target process, and discover where your SOPs need to adjust to practical constraints.

Use Cases

Leading manufacturers trust our software

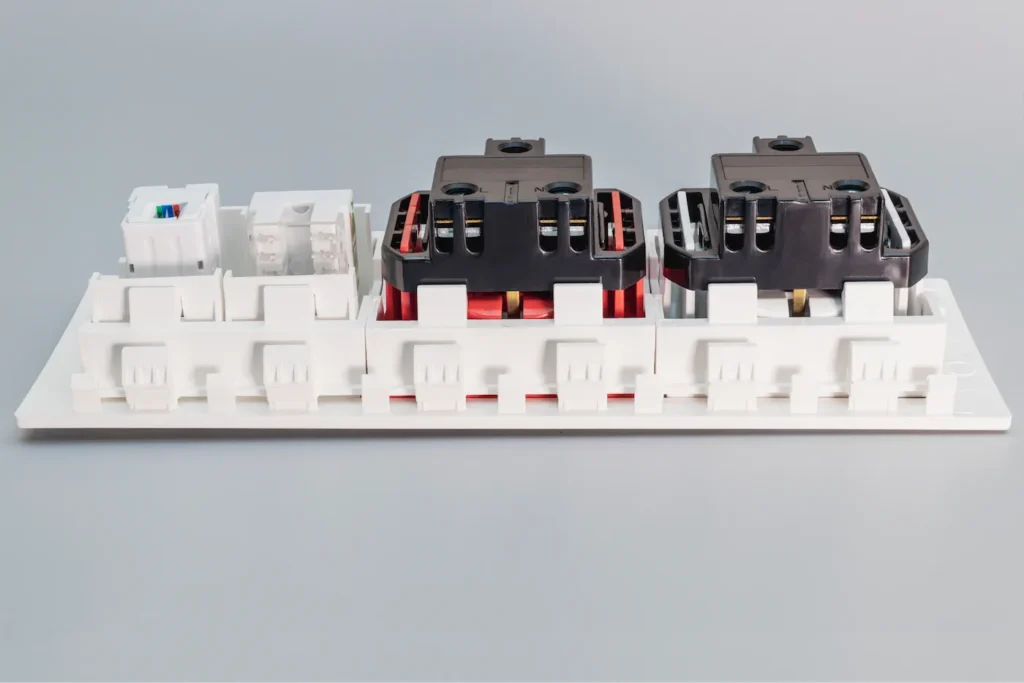

Appliances

- A manufacturer of high-mix appliances needed to tackle variant-specific bottlenecks in their production lines.

- By deploying process mining, they analyzed their material flow dynamically, which uncovered previously hidden bottlenecks.

- This resulted in more streamlined processes and enhanced throughput.

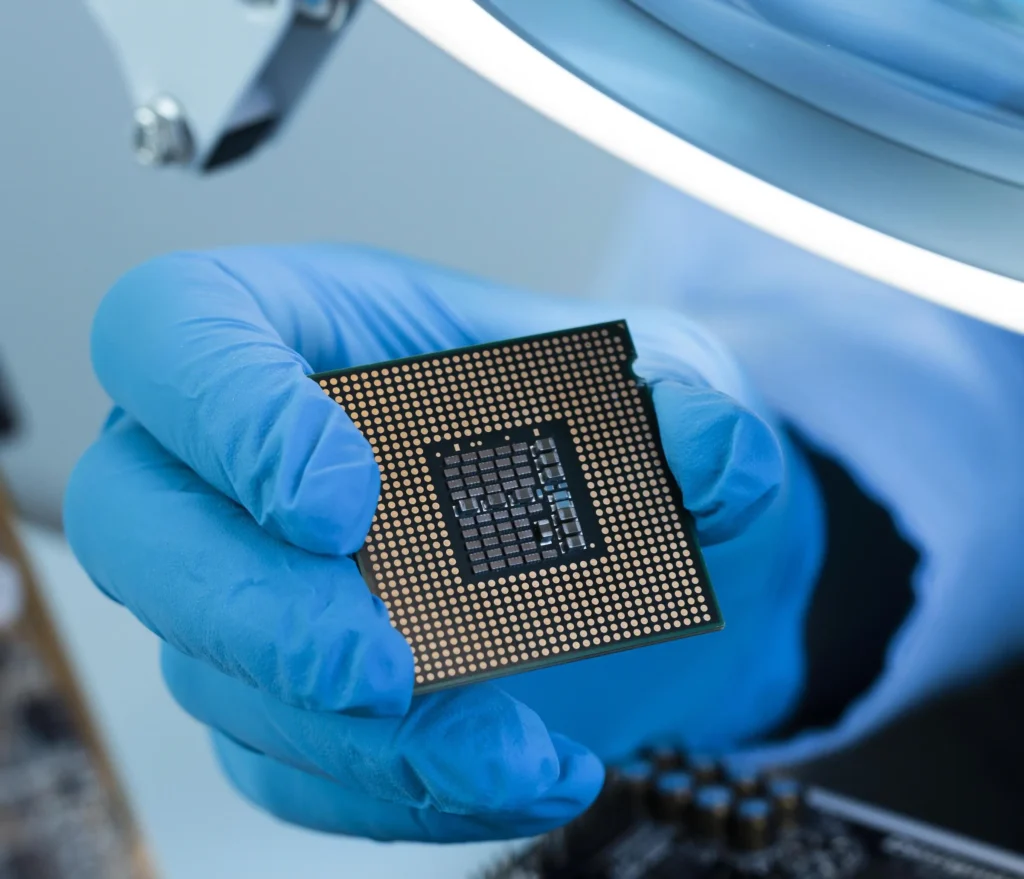

Semiconductors

- Semiconductor manufacturers frequently encounter unintended loops in their processes, leading to shifting bottlenecks.

- The Miner software dynamically analyzes these processes and pinpoints the locations of process deviations in real-time.

- This approach streamlines the production flow and effectively manages the impact of shifting bottlenecks.

Home Safety Electronics

- Multi-line factories with highly flexible material flows are challenging to analyze with conventional value stream mapping techniques.

- The Miner effectively goes beyond these static methods by dynamically exploring and analyzing material movements at any selected time.

- The actionable insights generated from the Miner directly support the reduction of cycle times and buffer inventories.