Blog

Process Mining: A new take on material flow analysis in manufacturing

Traditional methods for throughput improvement provide only a static view of manufacturing processes. This article explores process mining as a dynamic alternative. We analyze its application in bottleneck analysis, inventory analysis, and process variance analysis within manufacturing.

Why new process mapping methods are needed

Increasing the rate at which parts flow through a factory is a key objective in manufacturing. Better material flow can be achieved by eliminating three key obstacles: bottlenecks, process variation, and non-value-adding activities. Identifying and eliminating these obstacles is a key task for manufacturers. However, in practice, the dynamic nature of manufacturing processes often makes this task challenging. Conventional problem-solving methods frequently fall short in capturing the subtleties necessary to detect inefficiencies in material flows.

To visualize and understand their material flows, manufacturers regularly turn to manual process mapping methods. A common process mapping method is Value Stream Mapping (VSM), which has become a standard to uncover areas for improvement by illustrating both material and information flows within a factory. This provides a snapshot of the flows through a factory and supports manufacturers to analyze inefficiencies for the period of observation. However, as current process mapping tools are static (i.e., they only show the state of operations for a particular observation period), they are less effective when the material flows dynamically change over time. Moreover, existing methods require high manual effort, which limits their applicability in factories with high complexity. This leads to undiscovered inefficiencies and suboptimal process improvements.

This article explores how process mining can address the limitations of traditional process mapping methods. Process mining is a recent innovation in information system research that leverages event log data to dynamically analyze process flows. Despite noticeable success in other areas, such as service operations and supply chain processes, the potential for applications in manufacturing has not yet been fully recognized. Therefore, we will discuss three key use cases of process mining in manufacturing: bottleneck analysis, inventory analysis, and process variance analysis. Each use case will highlight how process mining offers significant advantages over traditional approaches for material flow analysis and helps manufacturers identify even the smallest inefficiencies.

How process mining enables better material flow analysis

Process mining is a technique for analyzing process flows based on event log data. An event log is a record of activities, capturing at minimum the sequence and timing of steps as they occur. For instance, in manufacturing, each step in a production process can generate an event log entry. Such entries include details like what happened, when it happened, and potential further information (e.g., on which machine, which operator, what costs). Process mining can use these event logs to understand how individual parts flow from one process step to another, thereby uncovering inefficiencies and throughput improvement opportunities.

So what data can be used for process mining in manufacturing? Key data includes a unique unit ID (typically the part or batch number), incoming and outgoing process timestamps (e.g., from 08:55 to 09:05), activity names (e.g., assembly and testing), and equipment names used to process a part. This information tracks each product unit’s journey through various stages of production.

The table below offers a glimpse into how this data might be structured in a manufacturing process involving assembly and testing steps, with each entry capturing a specific moment in the production flow. For most manufacturers, these event logs are readily available in their IT systems (even though they might not know it), most commonly in the format of XES or CSV files.

Although process mining was originally not developed for manufacturing, its application in this field is very promising. Its ability to provide insights into a factory’s material flow by aggregating the insights from individual product units is highly valuable. Given these opportunities, it is surprising that, to date, the adoption of this technique remains limited.

We identify three major reasons for the low adoption rate: (i) data acquisition, (ii) data processing, and (iii) value generation.

First, manufacturers often have a mix of newer and older machines that might be not digitized and do not provide the required data. However, in these situations, simple low-cost retrofit solutions can be applied to collect the required data. For instance, data matrix codes can be attached to part carriers, which are then read before and after a process with off-the-shelf scanners. In our experience, obtaining a first view on the data can be achieved in less than a day.

Second, manufacturing is often characterized by the convergence and combination of different parts. This has for long been a challenge for process mining, as the connection to one specific unit ID made it difficult to visualize and explore cases in which IDs are merging. However, due to recent developments in the field, object-centric process mining helps to overcome this hurdle.

Third, manufacturers are missing an overview of concrete use cases, which guides them how process mining can yield tangible improvement opportunities. This article sheds light on these opportunities by presenting three use cases how process mining can be used in manufacturing.

Example 1: Bottleneck analysis

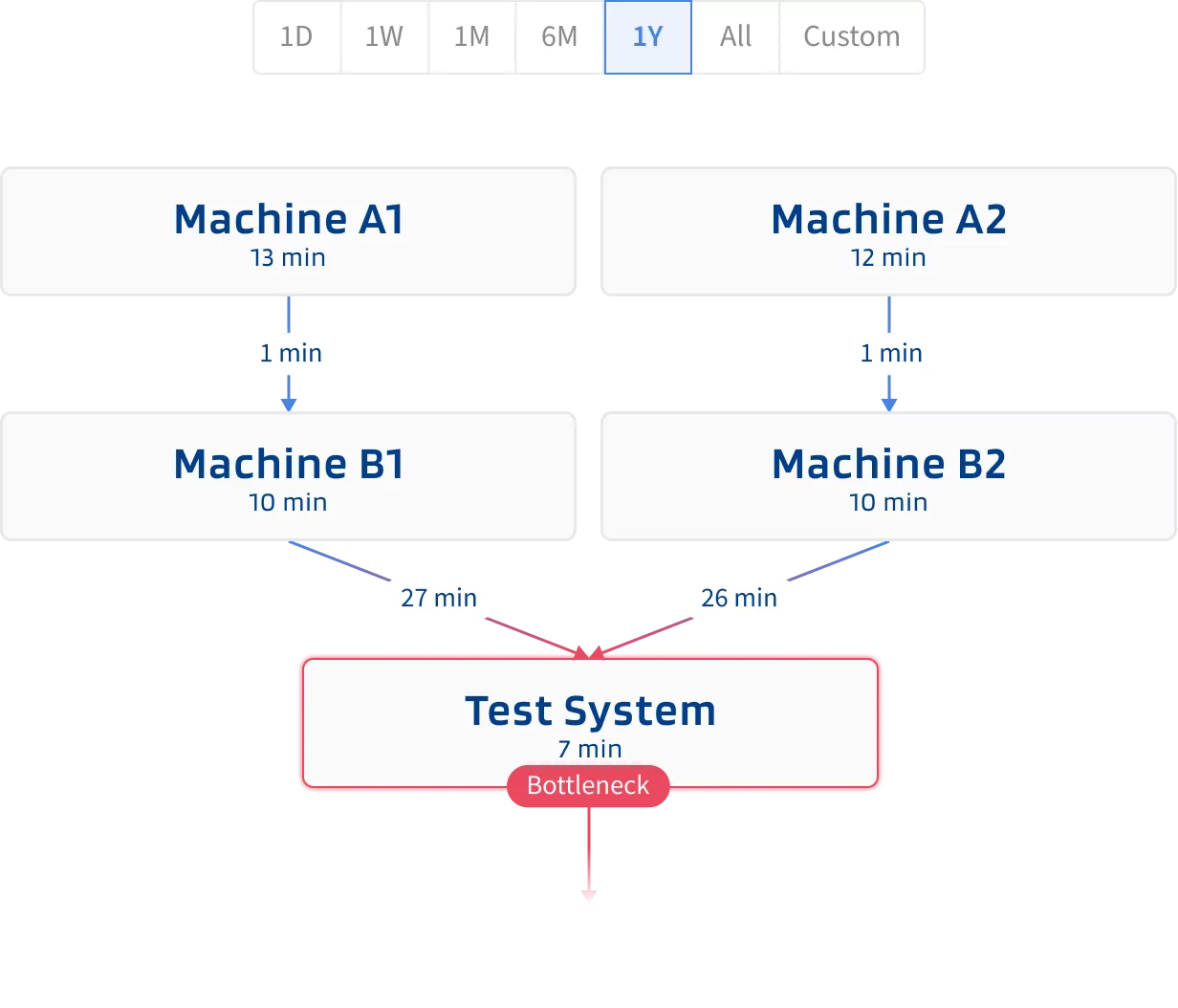

One of the key challenges in manufacturing is to identify and resolve bottlenecks that hinder efficient material flow. Process mining offers a unique solution to this challenge. By analyzing event log data, it provides a detailed “replay” of the material flow through each step of the manufacturing process. This approach enables manufacturers to observe the journey of each part in real-time and retrospectively.

Through process mining, manufacturers can accurately estimate how long parts spend at each stage of a factory (i.e., cycle time), including the time spent waiting before and after each process step (i.e., waiting time). This detailed analysis helps in pinpointing specific improvement areas, be it a machine or a process step, where delays frequently occur. By identifying these bottlenecks, manufacturers gain valuable insights into which processes are constraining the throughput of the entire factory.

The main advantage of process mining over traditional approaches lies in its dynamic capabilities, which allows for the detection of bottlenecks that may shift from one process step to another within specific time intervals. For example, in more complex production setups, where multiple product variants are produced on the same production line, each variant, each shift, and each sequence of machines might have a different bottleneck. Process mining is capable of identifying these specific bottlenecks independent of when they occur, thereby providing insights that are crucial for effectively managing the productivity of complex factories.

Example 2: Inventory analysis

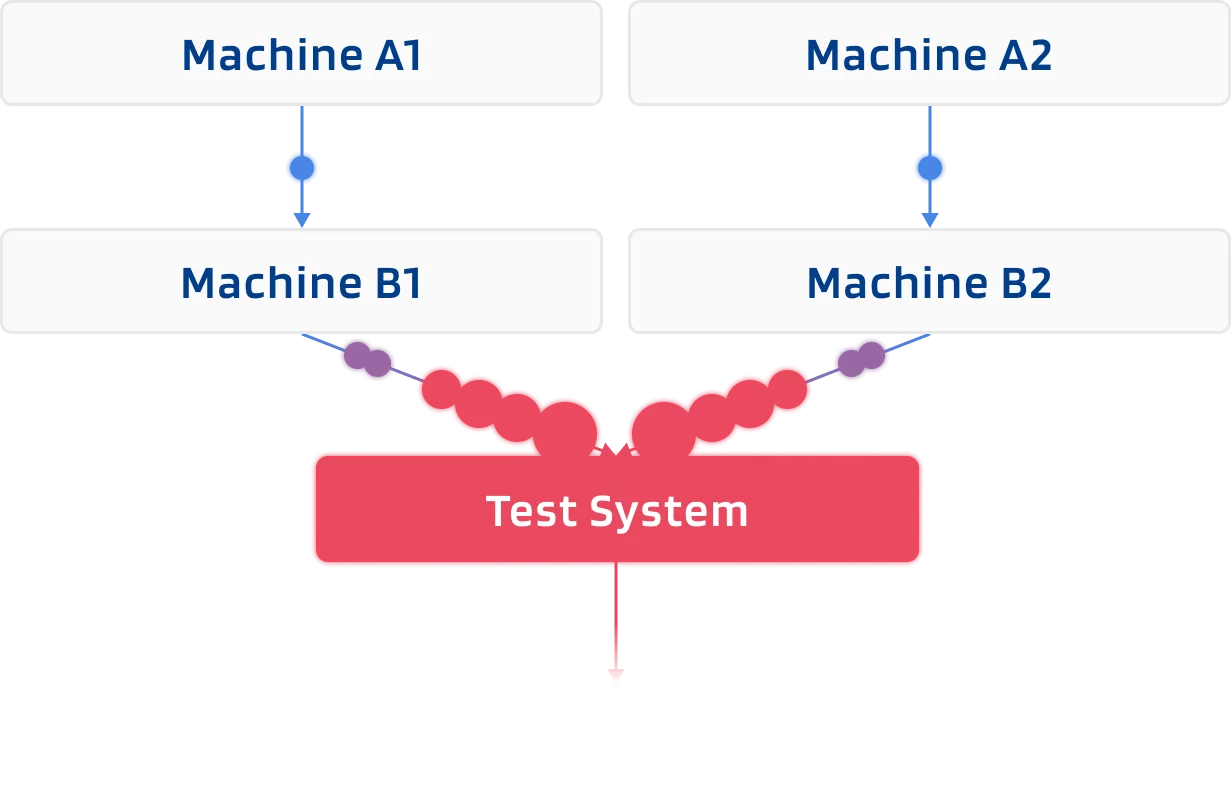

Following the identification of bottlenecks, another critical application is the reduction of (buffer) inventory between machines. Just as process mining helps identifying slow processes, it also illuminates areas where excessive inventory accumulates before and after an activity. This insight is invaluable for streamlining buffer inventories, ensuring that resources are not unnecessarily tied up in idle stock – and, at the same time, not starving due to missing parts.

Process mining essentially enables a dynamic form of value stream mapping, which offers a real-time view of inventory levels throughout a factory. It provides insights on the inventory levels between each process step at any given point of time. By analyzing these data, manufacturers can allocate their resources more effectively, minimize inventory holding costs (especially in areas preceding or following bottlenecks), and reduce lead times.

Example 3: Process variance analysis

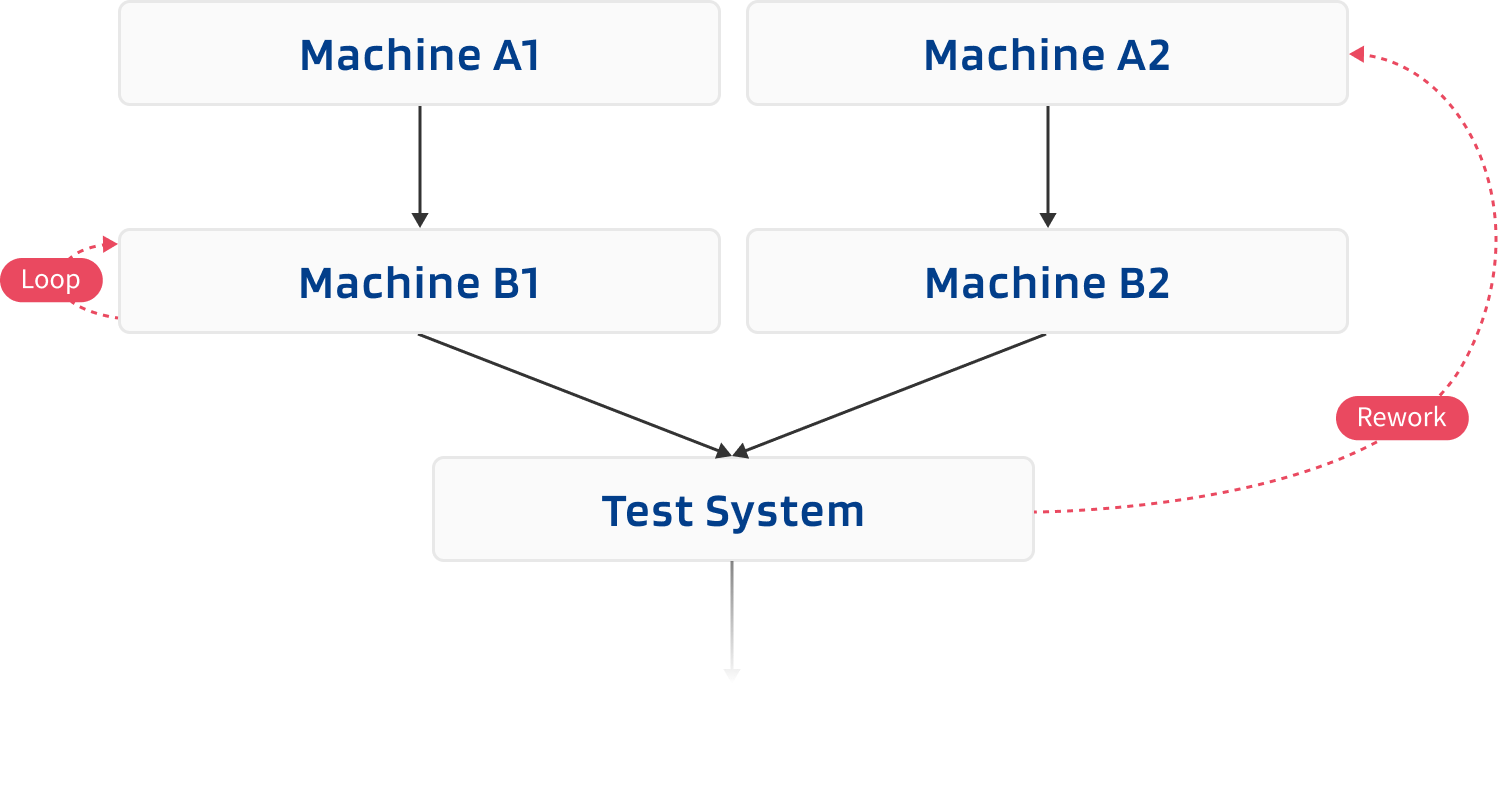

Another key objective is to detect deviations from the intended process flow. In process mining, the match between the actual process sequence and the intended process sequence is referred to as conformance. Process conformance checking aims at comparing the target process model with the actual process execution. This involves analyzing event logs to see whether the sequence in which a part travels through a factory adheres to the pre-defined flow.

Deviations from the intended process flow can have two reasons: (i) either the observed process shows unintended deviations, such as rework or unexpected loops, or (ii) the master data used to create the target process model is incorrect (e.g., master data not updated). Process mining allows for a detailed analysis of these process deviations.

The conformance of process flows can be quantified by different measures (e.g., “fitness”), which shows how well each actual process matches the intended process. This helps in identifying mismatches between the actual events and the as-designed process flow. These insights are crucial for aligning the actual manufacturing process with the intended design.

Unlike static process mapping methods, which only provide a limited snapshot of the material flow, process mining offers a dynamic, ongoing analysis. It captures a comprehensive view of all deviations, not just the ones visible at a particular moment. This dynamic capability is essential for ensuring manufacturing processes consistently adhere to their intended designs and to continuously update the design process to obtain proper master data, both of which is crucial for improving material flow throughout factories.

Outlook

Process mining offers significant advancements in productivity improvement for manufacturing. Utilizing untapped event log data, which manufacturers frequently store hidden in their operational history, it provides a dynamic and detailed perspective on inefficiencies in material flows. Unlike traditional process mapping, process mining offers deeper insights by dynamically analyzing the as-realized process flow throughout a factory. This enables manufacturers to identify bottlenecks, manage inventory effectively, and ensure process conformity.

Anticipated advancements in the field promise to expand the capabilities of process mining significantly. For instance, the emergence of AI-based chatbots could significantly enhance the scope of prescriptive process mining. Chatbots enable a direct interaction with a process model, thereby allowing even inexperienced analysts to ask specific questions on complex material flows (e.g., “What is the bottleneck of product A during Q1 2024 and what is the best way of removing it?”).

With recent trends, such as mass customization, the analysis of material flows becomes increasingly complex. Process mining emerges as a powerful tool for informed decision-making and achieving operational excellence.

We thank Dr. Rafael Lorenz for contributing to this article. For a detailed exploration of how process mining can be used in manufacturing, we refer interested readers to our paper in the International Journal of Production Research.